Realizing Ultimate Mass Transfer Efficiency - Metal Saddle Ring

Time:2025-12-17

In the pursuit of higher separation efficiency and lower energy consumption in modern industrial processes, the selection of packings is the core. The metal intalox saddle ring, as the culmination of the advantages of ring packing and saddle packing, achieves an excellent balance between gas-liquid distribution, mass transfer efficiency, and flux with its unique structural design. This article will conduct an in-depth technical analysis of the metal saddle ring from multiple dimensions, including its design philosophy, fluid dynamics characteristics, application scenarios, and comparison with other fillers.

1、Design philosophy: How structure determines performance

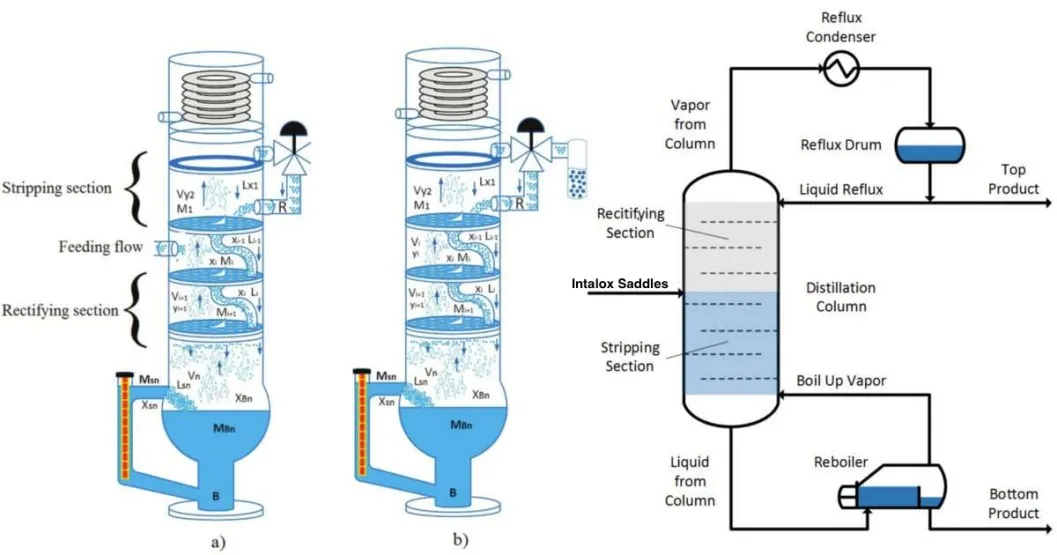

Metal saddle ring, commonly known as Intalox saddle ring packing, is not simply a ring or saddle shape, but a clever composite. Its structural characteristics can be summarized as follows:

1). Open structure design: It inherits the open structure of saddle shaped packing, avoiding the nesting and shielding between packing particles, allowing the space inside the packing layer to be fully utilized. This design greatly reduces bed resistance and ensures smooth gas-liquid flow channels.

2). Continuity of inner and outer surfaces: Its unique curved sidewalls form a continuous and smooth inner and outer surface. This structure enables the liquid to form a uniform liquid film during the flow process, rather than discrete droplets, thereby providing a stable and efficient mass transfer interface.

3). Enhance turbulence and redistribution capability: The flange structure (also known as tongue) on both sides of the packing is the essence of its design. These tongue blades not only increase mechanical strength, but more importantly, they can effectively cut fluids, generate moderate turbulence, break the boundary layer, and enhance mass transfer. At the same time, as the liquid flows through each packing unit, the tongue can act as a "redistributor" to redirect the liquid towards the center or side walls, continuously correcting the distribution of the liquid on the tower section and effectively overcoming the "wall flow" phenomenon.

2、Analysis of Fluid Mechanics and Mass Transfer Performance

The above structure of the metal saddle ring directly translates into the following excellent performance parameters:

* Extremely low pressure drop: Due to its open structure and smooth gas channels, the resistance of gas passing through the packing layer is very low. This means that at the same processing capacity, the power consumption (fan or compressor energy consumption) is lower, or the equipment is allowed to operate at higher gas speeds without flooding.

* High throughput: The low pressure drop characteristic directly endows the metal saddle ring with extremely high throughput processing capability. For operating conditions that require handling large amounts of gas (such as atmospheric environment treatment, large-scale chemical plants), this means that smaller diameter towers can be used or increased production can be carried out in existing towers.

* High mass transfer efficiency: The continuous liquid film surface, efficient liquid redistribution ability, and moderate turbulence generated internally jointly ensure that gas-liquid phases can fully and efficiently come into contact. It has a high theoretical number of plates per meter and a low equivalent plate height (HETP), which can achieve high-precision separation requirements.

* High operational flexibility: Metal saddle rings can maintain stable high performance over a wide range of gas-liquid loads. Even if the feeding conditions fluctuate, it can maintain a good separation effect, ensuring the stability and flexibility of the production process.

3、Typical application scenarios

The comprehensive performance advantages of metal saddle rings make them the preferred choice in situations with strict requirements for efficiency, energy consumption, and flux:

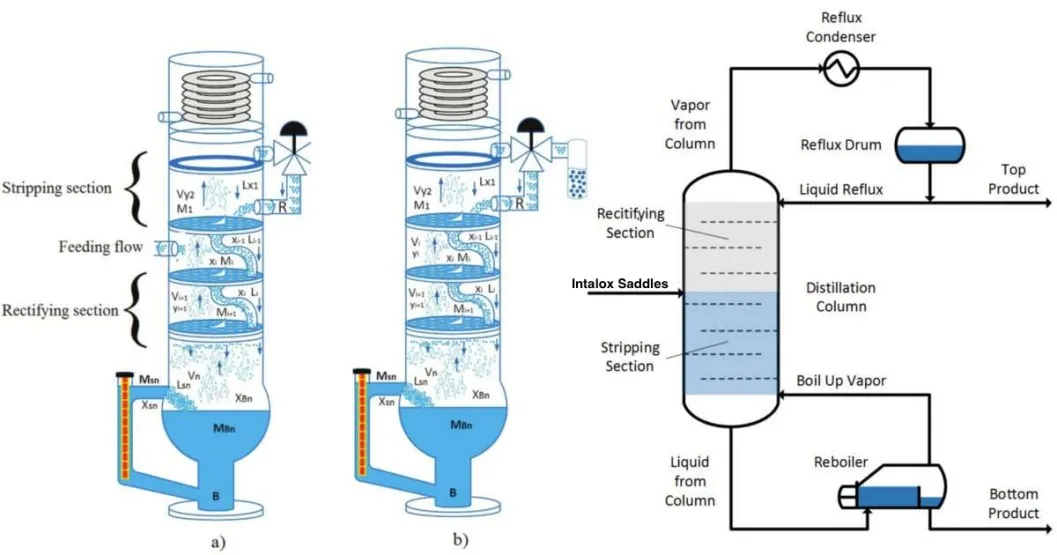

1). Vacuum distillation: This is a classic application field of metal saddle rings. Under vacuum operation, the system is extremely sensitive to pressure drop. The low pressure drop characteristics of metal saddle rings can significantly reduce the vacuum requirements and energy consumption of tower kettles, while maintaining high separation efficiency, which is crucial for the separation of thermosensitive systems.

2). High throughput heat exchange process: In some equipment that combines mass and heat transfer, such as large cooling towers and stripping towers, their high flux and efficient mass transfer capabilities can significantly reduce equipment volume and investment costs.

3). Treatment of corrosive materials: When the process medium is corrosive, saddle rings made of special metals such as Hastelloy, titanium, Monel alloy, etc. can be used. The combination of their structural advantages and corrosion resistance provides a reliable solution.

4). Capacity expansion and renovation of existing towers: When it is necessary to improve the processing capacity of existing equipment, replacing the old packing with metal saddle rings (such as Raschig rings or even some low flux regular packing) is an effective means with less investment and quick results.

If the metal pall Ring is a "versatile warrior", then the metal Saddle Ring is more like a "special forces soldier". When pressure drop and flux are the primary considerations, especially in vacuum environments and large towers that require extremely uniform liquid distribution, metal saddle rings are undoubtedly the top choice.

OIM Chemical provides a full range of metal saddle rings ,pall rings, raschig ring etc, from standard materials to special alloys, from precise selection to technical support, to help your device achieve maximum efficiency and cost optimization. Welcome to contact our technical team for professional solutions tailored to your specific working conditions.

In the pursuit of higher separation efficiency and lower energy consumption in modern industrial processes, the selection of packings is the core. The metal intalox saddle ring, as the culmination of the advantages of ring packing and saddle packing, achieves an excellent balance between gas-liquid distribution, mass transfer efficiency, and flux with its unique structural design. This article will conduct an in-depth technical analysis of the metal saddle ring from multiple dimensions, including its design philosophy, fluid dynamics characteristics, application scenarios, and comparison with other fillers.

1、Design philosophy: How structure determines performance

Metal saddle ring, commonly known as Intalox saddle ring packing, is not simply a ring or saddle shape, but a clever composite. Its structural characteristics can be summarized as follows:

1). Open structure design: It inherits the open structure of saddle shaped packing, avoiding the nesting and shielding between packing particles, allowing the space inside the packing layer to be fully utilized. This design greatly reduces bed resistance and ensures smooth gas-liquid flow channels.

2). Continuity of inner and outer surfaces: Its unique curved sidewalls form a continuous and smooth inner and outer surface. This structure enables the liquid to form a uniform liquid film during the flow process, rather than discrete droplets, thereby providing a stable and efficient mass transfer interface.

3). Enhance turbulence and redistribution capability: The flange structure (also known as tongue) on both sides of the packing is the essence of its design. These tongue blades not only increase mechanical strength, but more importantly, they can effectively cut fluids, generate moderate turbulence, break the boundary layer, and enhance mass transfer. At the same time, as the liquid flows through each packing unit, the tongue can act as a "redistributor" to redirect the liquid towards the center or side walls, continuously correcting the distribution of the liquid on the tower section and effectively overcoming the "wall flow" phenomenon.

2、Analysis of Fluid Mechanics and Mass Transfer Performance

The above structure of the metal saddle ring directly translates into the following excellent performance parameters:

* Extremely low pressure drop: Due to its open structure and smooth gas channels, the resistance of gas passing through the packing layer is very low. This means that at the same processing capacity, the power consumption (fan or compressor energy consumption) is lower, or the equipment is allowed to operate at higher gas speeds without flooding.

* High throughput: The low pressure drop characteristic directly endows the metal saddle ring with extremely high throughput processing capability. For operating conditions that require handling large amounts of gas (such as atmospheric environment treatment, large-scale chemical plants), this means that smaller diameter towers can be used or increased production can be carried out in existing towers.

* High mass transfer efficiency: The continuous liquid film surface, efficient liquid redistribution ability, and moderate turbulence generated internally jointly ensure that gas-liquid phases can fully and efficiently come into contact. It has a high theoretical number of plates per meter and a low equivalent plate height (HETP), which can achieve high-precision separation requirements.

* High operational flexibility: Metal saddle rings can maintain stable high performance over a wide range of gas-liquid loads. Even if the feeding conditions fluctuate, it can maintain a good separation effect, ensuring the stability and flexibility of the production process.

3、Typical application scenarios

The comprehensive performance advantages of metal saddle rings make them the preferred choice in situations with strict requirements for efficiency, energy consumption, and flux:

1). Vacuum distillation: This is a classic application field of metal saddle rings. Under vacuum operation, the system is extremely sensitive to pressure drop. The low pressure drop characteristics of metal saddle rings can significantly reduce the vacuum requirements and energy consumption of tower kettles, while maintaining high separation efficiency, which is crucial for the separation of thermosensitive systems.

2). High throughput heat exchange process: In some equipment that combines mass and heat transfer, such as large cooling towers and stripping towers, their high flux and efficient mass transfer capabilities can significantly reduce equipment volume and investment costs.

3). Treatment of corrosive materials: When the process medium is corrosive, saddle rings made of special metals such as Hastelloy, titanium, Monel alloy, etc. can be used. The combination of their structural advantages and corrosion resistance provides a reliable solution.

4). Capacity expansion and renovation of existing towers: When it is necessary to improve the processing capacity of existing equipment, replacing the old packing with metal saddle rings (such as Raschig rings or even some low flux regular packing) is an effective means with less investment and quick results.

If the metal pall Ring is a "versatile warrior", then the metal Saddle Ring is more like a "special forces soldier". When pressure drop and flux are the primary considerations, especially in vacuum environments and large towers that require extremely uniform liquid distribution, metal saddle rings are undoubtedly the top choice.

OIM Chemical provides a full range of metal saddle rings ,pall rings, raschig ring etc, from standard materials to special alloys, from precise selection to technical support, to help your device achieve maximum efficiency and cost optimization. Welcome to contact our technical team for professional solutions tailored to your specific working conditions.