Precision Adsorption Expert for Industrial Protection - Molecular Sieve

Time:2025-12-26

Have you ever been troubled by the following issues in the air separation unit, petrochemical production line, or natural gas processing plant that you manage?

* Does the dew point not meet the standard lead to equipment ice blockage and catalyst poisoning?

* Does the fluctuation of product purity affect the final quality and selling price?

* High energy consumption and difficult to control operating costs?

Many times, the root of the problem lies in the precision and reliability of the adsorption separation process. Today, we will delve into how Molecular Sieve 4A, an adsorbent that has become a standard solution in many demanding industrial scenarios, can become an indispensable "guardian" in your processes with its precise performance.

1、Core principle: Not just a sieve, but also an "intelligent magnet"

1). Accurate "molecular sieving" (at the molecular size level)

*Its crystal aperture is 4 angstroms (4Å), which is 0.4 nm. This is like a standard ruler, allowing only molecules with a diameter smaller than this value to enter.

*It can adsorb water molecules (H 2O, 2.6 Å), carbon dioxide (CO2, 3.3 Å), and sulfur dioxide (SO2, 3.6 Å).

*It can block propane (C3H8, 4.3Å) and most larger hydrocarbon molecules.

2). Powerful "polar adsorption" (at the molecular polarity level)

* The sodium ions in the skeleton generate a strong local positive electric field.

* It has a strong affinity for polar molecules, especially water, and can achieve deep adsorption even under low concentration and high flow rate conditions.

This means that molecular sieve 4A provides dual protection. It can not only screen molecules based on their size, but also actively and strongly capture the "problematic molecules" that are most likely to disrupt your process flow - mainly water and acidic gases.

2、Key industrial application scenarios

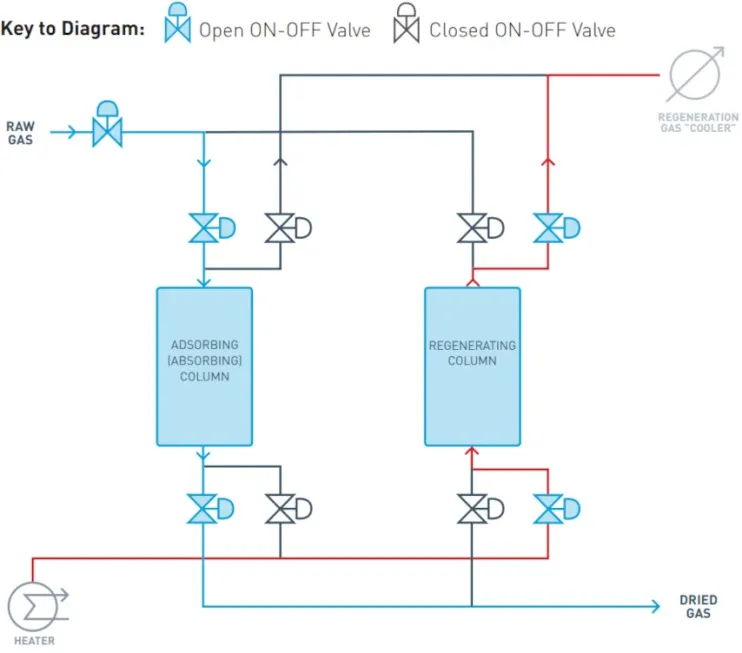

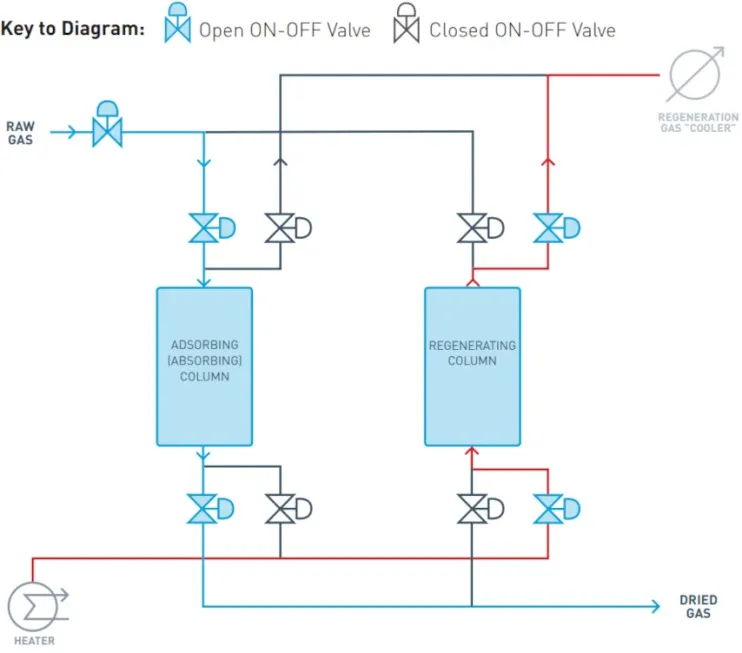

Scenario 1: Deep protection in front of the air separation unit - why is it necessary?

* Point: If the water and CO2 in the compressed air are not completely removed, they will freeze into ice in the cryogenic air separation tower, block valves, pipelines, and heat exchangers, resulting in shutdown and huge losses.

* Solution: Molecular sieve 4A. It ensures that the dew point of the raw air is reduced to below -70°C before entering the main heat exchanger, and almost 100% CO2 is removed. This' absolute dryness' is a prerequisite for the long-term, stable, and safe operation of air separation units.

* Benefit: Maximize the online rate of the device and avoid huge production losses caused by unplanned parking.

Scenario 2: Value Purification in Petrochemical Processes

* Point: It is necessary to efficiently separate straight chain alkanes (n-alkanes) from mixed hydrocarbons (such as naphtha) as high-quality raw materials for producing advanced detergents or plasticizers.

* Solution: Molecular sieve 4A. Utilizing its precise 4Å pore size, it selectively adsorbs smaller diameter straight chain alkanes while blocking branched isomers and aromatic hydrocarbons. This is a purely physical process, which can be desorbed by simple depressurization to obtain high-purity n-alkanes.

* Benefit: Obtain a higher value product stream and enhance the overall profitability of the industry chain. The energy consumption of the process is much lower than that of precision distillation, making it more economical.

Scenario 3: Natural gas and inert gas purification - ensuring downstream equipment and product quality

* Points: Moisture and acidic gases (CO2, H2S) in natural gas, biogas, or protective gases (such as N2, H2) can corrode pipelines, poison precious metal catalysts, and affect the quality of downstream chemical products.

* Solution: Molecular sieve 4A. Simultaneously perform deep dehydration and CO2 removal in the same bed, simplifying the process flow. For H2S, although 4A itself has a certain adsorption capacity, we can provide specific modified 4A models to enhance its sulfur capacity in high concentration situations.

* Benefit: Protect downstream core assets (catalysts, compressors) to ensure the purity and consistency of the final product.

3、How to choose a reliable supplier of molecular sieve 4A?

Choosing molecular sieves is not only about purchasing a product, but also about choosing a long-term partner for your production line. Please evaluate from the following three dimensions:

1). Adsorption capacity and retention rate (related to operating costs)

* Q: What is the equilibrium adsorption capacity of the product under specific temperature, pressure, and humidity conditions?

*Key point: High initial adsorption capacity means longer operating cycles, less regeneration frequency, and directly reduces energy consumption. More importantly, after hundreds of regeneration cycles, its capacity retention rate should still be excellent.

2). Mechanical strength and wear rate (related to system pressure drop and lifespan)

* Q: What are the test data for compressive strength and wear rate of the product?

* Key point: Low strength molecular sieves are prone to pulverization during loading, operation, and pressure fluctuations. The generated dust can clog pipelines, increase system pressure drop, and in severe cases, lead to shutdown for cleaning. High strength molecular sieves mean lower maintenance costs and longer service life.

3). Professional technical support and services (related to application effectiveness)

* Q: Can the supplier provide adsorbent selection and loading calculations based on our specific operating conditions (gas composition, temperature, pressure, flow rate)?

* Key point: A professional supplier can help you optimize your design, avoid "under loading" or "over design", and ensure maximum return on investment.

What we provide is not only molecular sieve 4A, but also a guarantee for stable production.

Our molecular sieve 4A achieves the optimal balance between adsorption capacity, mechanical strength, and lifecycle cost through optimized synthesis and molding processes. We deeply understand that for you, time is output, and stability is profit. Choosing our product will bring more stable, economical, and efficient performance to your device.

Have you ever been troubled by the following issues in the air separation unit, petrochemical production line, or natural gas processing plant that you manage?

* Does the dew point not meet the standard lead to equipment ice blockage and catalyst poisoning?

* Does the fluctuation of product purity affect the final quality and selling price?

* High energy consumption and difficult to control operating costs?

Many times, the root of the problem lies in the precision and reliability of the adsorption separation process. Today, we will delve into how Molecular Sieve 4A, an adsorbent that has become a standard solution in many demanding industrial scenarios, can become an indispensable "guardian" in your processes with its precise performance.

1、Core principle: Not just a sieve, but also an "intelligent magnet"

1). Accurate "molecular sieving" (at the molecular size level)

*Its crystal aperture is 4 angstroms (4Å), which is 0.4 nm. This is like a standard ruler, allowing only molecules with a diameter smaller than this value to enter.

*It can adsorb water molecules (H 2O, 2.6 Å), carbon dioxide (CO2, 3.3 Å), and sulfur dioxide (SO2, 3.6 Å).

*It can block propane (C3H8, 4.3Å) and most larger hydrocarbon molecules.

2). Powerful "polar adsorption" (at the molecular polarity level)

* The sodium ions in the skeleton generate a strong local positive electric field.

* It has a strong affinity for polar molecules, especially water, and can achieve deep adsorption even under low concentration and high flow rate conditions.

This means that molecular sieve 4A provides dual protection. It can not only screen molecules based on their size, but also actively and strongly capture the "problematic molecules" that are most likely to disrupt your process flow - mainly water and acidic gases.

2、Key industrial application scenarios

Scenario 1: Deep protection in front of the air separation unit - why is it necessary?

* Point: If the water and CO2 in the compressed air are not completely removed, they will freeze into ice in the cryogenic air separation tower, block valves, pipelines, and heat exchangers, resulting in shutdown and huge losses.

* Solution: Molecular sieve 4A. It ensures that the dew point of the raw air is reduced to below -70°C before entering the main heat exchanger, and almost 100% CO2 is removed. This' absolute dryness' is a prerequisite for the long-term, stable, and safe operation of air separation units.

* Benefit: Maximize the online rate of the device and avoid huge production losses caused by unplanned parking.

Scenario 2: Value Purification in Petrochemical Processes

* Point: It is necessary to efficiently separate straight chain alkanes (n-alkanes) from mixed hydrocarbons (such as naphtha) as high-quality raw materials for producing advanced detergents or plasticizers.

* Solution: Molecular sieve 4A. Utilizing its precise 4Å pore size, it selectively adsorbs smaller diameter straight chain alkanes while blocking branched isomers and aromatic hydrocarbons. This is a purely physical process, which can be desorbed by simple depressurization to obtain high-purity n-alkanes.

* Benefit: Obtain a higher value product stream and enhance the overall profitability of the industry chain. The energy consumption of the process is much lower than that of precision distillation, making it more economical.

Scenario 3: Natural gas and inert gas purification - ensuring downstream equipment and product quality

* Points: Moisture and acidic gases (CO2, H2S) in natural gas, biogas, or protective gases (such as N2, H2) can corrode pipelines, poison precious metal catalysts, and affect the quality of downstream chemical products.

* Solution: Molecular sieve 4A. Simultaneously perform deep dehydration and CO2 removal in the same bed, simplifying the process flow. For H2S, although 4A itself has a certain adsorption capacity, we can provide specific modified 4A models to enhance its sulfur capacity in high concentration situations.

* Benefit: Protect downstream core assets (catalysts, compressors) to ensure the purity and consistency of the final product.

3、How to choose a reliable supplier of molecular sieve 4A?

Choosing molecular sieves is not only about purchasing a product, but also about choosing a long-term partner for your production line. Please evaluate from the following three dimensions:

1). Adsorption capacity and retention rate (related to operating costs)

* Q: What is the equilibrium adsorption capacity of the product under specific temperature, pressure, and humidity conditions?

*Key point: High initial adsorption capacity means longer operating cycles, less regeneration frequency, and directly reduces energy consumption. More importantly, after hundreds of regeneration cycles, its capacity retention rate should still be excellent.

2). Mechanical strength and wear rate (related to system pressure drop and lifespan)

* Q: What are the test data for compressive strength and wear rate of the product?

* Key point: Low strength molecular sieves are prone to pulverization during loading, operation, and pressure fluctuations. The generated dust can clog pipelines, increase system pressure drop, and in severe cases, lead to shutdown for cleaning. High strength molecular sieves mean lower maintenance costs and longer service life.

3). Professional technical support and services (related to application effectiveness)

* Q: Can the supplier provide adsorbent selection and loading calculations based on our specific operating conditions (gas composition, temperature, pressure, flow rate)?

* Key point: A professional supplier can help you optimize your design, avoid "under loading" or "over design", and ensure maximum return on investment.

What we provide is not only molecular sieve 4A, but also a guarantee for stable production.

Our molecular sieve 4A achieves the optimal balance between adsorption capacity, mechanical strength, and lifecycle cost through optimized synthesis and molding processes. We deeply understand that for you, time is output, and stability is profit. Choosing our product will bring more stable, economical, and efficient performance to your device.