How to choose suitable inert ceramic balls accurately?

Time:2025-10-23

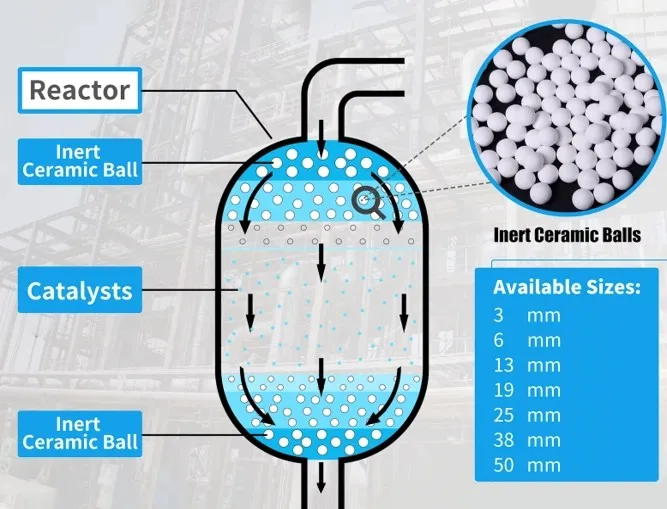

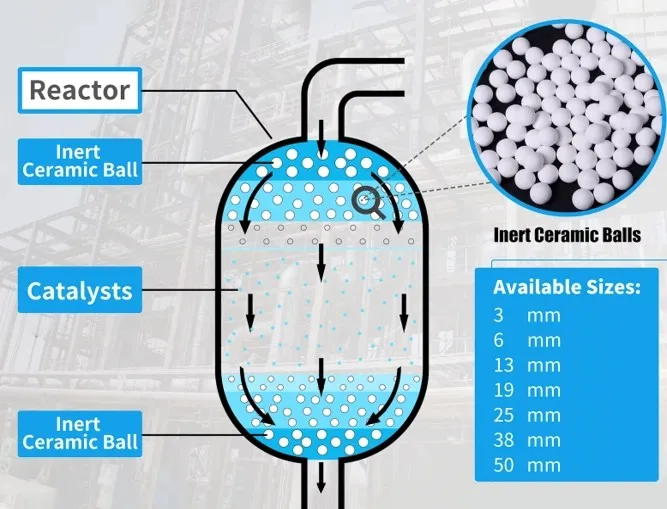

In packing towers, although inert ceramic balls do not participate in chemical reactions directly, they serve as supporting media, which are crucial for ensuring the efficient and stable operation of the entire system. Wrong choices may lead to a significant increase in pressure drop, uneven distribution, and even collapse of the packing layer. This article aims to provide our customers with a clear and professional guide for selecting inert ceramic balls.

One: The core function of inert ceramic balls

Before selection, we need to understand 3 key roles that ceramic balls play inside the tower:

1). Support protection: Located at the bottom of the packing layer, preventing the main packing (such as structured packing, Raschig ring, etc.) from falling off to the collector and bearing the huge weight of the upper packing.

2). Uniform distribution: Located at the top of the packing layer, it helps to pre distribute the gas/liquid fluid entering the tower, avoid bias flow, and ensure sufficient contact with the main packing.

3). Heat and mass transfer: The ceramic ball layer itself can also provide a certain specific surface area, which can assist in heat and mass transfer processes in certain applications. Clarifying which functions your ceramic ball mainly undertakes is the first step in selecting the correct one.

Two: Key selection parameters

Choosing the appropriate inert ceramic ball requires comprehensive consideration of the following 4 core factors:

1. Material and chemical inertness: The word "inertness" -- Ceramic balls must be able to withstand the environment of the process medium.

*Chemical composition:

1) Comon inert ceramic balls (Al2O3 ≥ 17%): Suitable for non strong acid and non strong alkali conventional working conditions, such as petroleum refining, natural gas treatment, general chemical separation, etc. It is the most cost-effective choice.

2) High alumina ceramic ball (Al2O3 ≥ 99%): It has extremely high mechanical strength and corrosion resistance, suitable for high temperature, high pressure, or harsh corrosive environments such as hydrofluoric acid (HF).

3) Zirconium alumina ceramic balls (containing ZrO2): Have ultra-high wear resistance and corrosion resistance, especially suitable for fluidized bed reactors with severe wear or extreme corrosion conditions.

2. Size and grading matching: The most intuitive and crucial aspect. The principle is to increase from top to bottom and layer by layer.

* Size selection criteria:

1) Top cover layer: Usually, ceramic balls with smaller diameters (such as Φ 3mm, Φ 6mm) are selected to disperse the liquid and achieve uniform distribution.

2) Intermediate transition layer: Choose medium-sized ceramic balls (such as Φ 15mm, Φ 20mm) to serve as a bridge between the upper and lower layers.

3) Bottom support layer: The ceramic ball with the largest diameter (such as Φ 25mm, Φ 38mm, or even larger) must be selected to ensure sufficient strength to support the entire packing layer and ensure smooth discharge of the bottom fluid of the tower.

* Grading rules:

1) The diameter of each layer of ceramic balls should be 2-3 times larger than the diameter of the packings (or ceramic balls) above it.

2) The filling height of each layer of ceramic balls is usually 5-10 times their diameter to ensure stable support and distribution.

For example, for a tower using Φ 25mm Raschig ring as the main packings, the ceramic ball grading scheme can be as below:

*Bottom support layer: Φ 50mm inert ceramic ball, height~300mm

*Intermediate transition layer: Φ 25mm inert ceramic ball, height~150mm

*Top cover layer: Φ 10mm inert ceramic ball, height~100mm

(* Note: The specific plan needs to be accurately calculated based on the tower diameter and operating conditions)

3. Mechanical strength and wear resistance

Ceramic balls will withstand enormous static pressure and mutual friction during loading, operation, and maintenance processes. Low strength ceramic balls are prone to breakage, and the resulting fragments can clog the distributor or main packing, leading to an increase in pressure drop and a decrease in efficiency.

*Key indicators: compressive strength (N/particle) and wear ratio (%).

*Selection principle: For the support layer, especially in high towers, ceramic balls with extremely high compressive strength must be selected. Our high alumina ceramic balls perform excellently in this regard.

4. Thermal stability

If your process involves high-temperature operations (such as high-temperature reactors, converters), the ceramic balls must be able to withstand drastic temperature changes without cracking.

*Key indicator: thermal shock stability. Alumina balls with higher aluminum content usually have better thermal stability.

As your reliable partner, OIM Chemical can not only provide with high-quality inert ceramic balls which meet ASTM and other standards, but also offer following services:

* Free technical consultation: Our engineering team can provide you with the optimal ceramic ball grading scheme based on your specific process and tower internal structure diagram.

* Complete solution: We offer a complete line of tower internals from supporting grilles to inert ceramic balls, and then to main packing, ensuring system compatibility and optimal performance.

* Reliable quality assurance: Each batch of products before leaving factory comes with a quality inspection report to ensure that their chemical and physical properties meet your demanding requirements.

Choosing the appropriate inert ceramic ball is a low-cost, high return technological investment. If you are selecting for a new project or seeking performance optimization for an existing device, please contact our team immediately. By providing your process parameters, we will customize a customized ceramic ball selection and filling plan for you free of charge.

In packing towers, although inert ceramic balls do not participate in chemical reactions directly, they serve as supporting media, which are crucial for ensuring the efficient and stable operation of the entire system. Wrong choices may lead to a significant increase in pressure drop, uneven distribution, and even collapse of the packing layer. This article aims to provide our customers with a clear and professional guide for selecting inert ceramic balls.

One: The core function of inert ceramic balls

Before selection, we need to understand 3 key roles that ceramic balls play inside the tower:

1). Support protection: Located at the bottom of the packing layer, preventing the main packing (such as structured packing, Raschig ring, etc.) from falling off to the collector and bearing the huge weight of the upper packing.

2). Uniform distribution: Located at the top of the packing layer, it helps to pre distribute the gas/liquid fluid entering the tower, avoid bias flow, and ensure sufficient contact with the main packing.

3). Heat and mass transfer: The ceramic ball layer itself can also provide a certain specific surface area, which can assist in heat and mass transfer processes in certain applications. Clarifying which functions your ceramic ball mainly undertakes is the first step in selecting the correct one.

Two: Key selection parameters

Choosing the appropriate inert ceramic ball requires comprehensive consideration of the following 4 core factors:

1. Material and chemical inertness: The word "inertness" -- Ceramic balls must be able to withstand the environment of the process medium.

*Chemical composition:

1) Comon inert ceramic balls (Al2O3 ≥ 17%): Suitable for non strong acid and non strong alkali conventional working conditions, such as petroleum refining, natural gas treatment, general chemical separation, etc. It is the most cost-effective choice.

2) High alumina ceramic ball (Al2O3 ≥ 99%): It has extremely high mechanical strength and corrosion resistance, suitable for high temperature, high pressure, or harsh corrosive environments such as hydrofluoric acid (HF).

3) Zirconium alumina ceramic balls (containing ZrO2): Have ultra-high wear resistance and corrosion resistance, especially suitable for fluidized bed reactors with severe wear or extreme corrosion conditions.

2. Size and grading matching: The most intuitive and crucial aspect. The principle is to increase from top to bottom and layer by layer.

* Size selection criteria:

1) Top cover layer: Usually, ceramic balls with smaller diameters (such as Φ 3mm, Φ 6mm) are selected to disperse the liquid and achieve uniform distribution.

2) Intermediate transition layer: Choose medium-sized ceramic balls (such as Φ 15mm, Φ 20mm) to serve as a bridge between the upper and lower layers.

3) Bottom support layer: The ceramic ball with the largest diameter (such as Φ 25mm, Φ 38mm, or even larger) must be selected to ensure sufficient strength to support the entire packing layer and ensure smooth discharge of the bottom fluid of the tower.

* Grading rules:

1) The diameter of each layer of ceramic balls should be 2-3 times larger than the diameter of the packings (or ceramic balls) above it.

2) The filling height of each layer of ceramic balls is usually 5-10 times their diameter to ensure stable support and distribution.

For example, for a tower using Φ 25mm Raschig ring as the main packings, the ceramic ball grading scheme can be as below:

*Bottom support layer: Φ 50mm inert ceramic ball, height~300mm

*Intermediate transition layer: Φ 25mm inert ceramic ball, height~150mm

*Top cover layer: Φ 10mm inert ceramic ball, height~100mm

(* Note: The specific plan needs to be accurately calculated based on the tower diameter and operating conditions)

3. Mechanical strength and wear resistance

Ceramic balls will withstand enormous static pressure and mutual friction during loading, operation, and maintenance processes. Low strength ceramic balls are prone to breakage, and the resulting fragments can clog the distributor or main packing, leading to an increase in pressure drop and a decrease in efficiency.

*Key indicators: compressive strength (N/particle) and wear ratio (%).

*Selection principle: For the support layer, especially in high towers, ceramic balls with extremely high compressive strength must be selected. Our high alumina ceramic balls perform excellently in this regard.

4. Thermal stability

If your process involves high-temperature operations (such as high-temperature reactors, converters), the ceramic balls must be able to withstand drastic temperature changes without cracking.

*Key indicator: thermal shock stability. Alumina balls with higher aluminum content usually have better thermal stability.

As your reliable partner, OIM Chemical can not only provide with high-quality inert ceramic balls which meet ASTM and other standards, but also offer following services:

* Free technical consultation: Our engineering team can provide you with the optimal ceramic ball grading scheme based on your specific process and tower internal structure diagram.

* Complete solution: We offer a complete line of tower internals from supporting grilles to inert ceramic balls, and then to main packing, ensuring system compatibility and optimal performance.

* Reliable quality assurance: Each batch of products before leaving factory comes with a quality inspection report to ensure that their chemical and physical properties meet your demanding requirements.

Choosing the appropriate inert ceramic ball is a low-cost, high return technological investment. If you are selecting for a new project or seeking performance optimization for an existing device, please contact our team immediately. By providing your process parameters, we will customize a customized ceramic ball selection and filling plan for you free of charge.