Deliver high ceramic alumina balls to Middle East

Time:2025-11-20

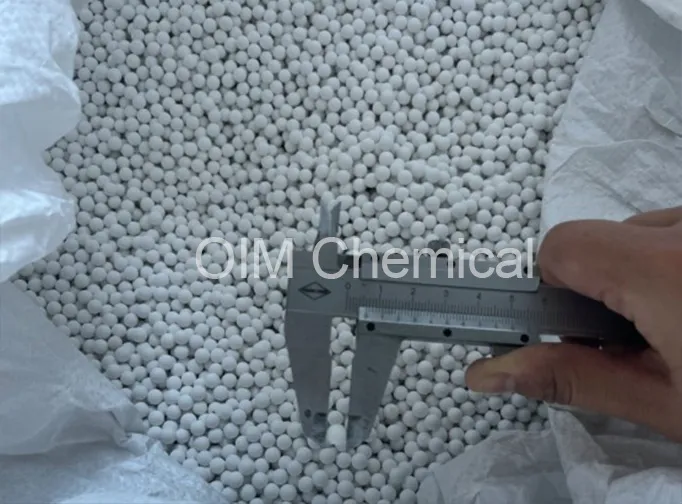

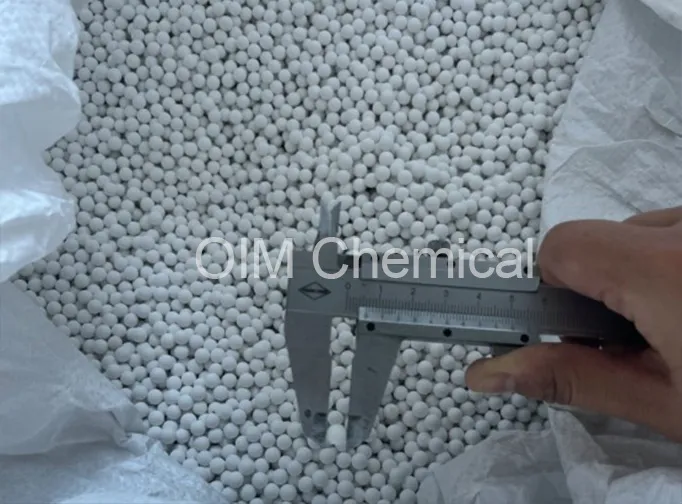

In August, one of customer from Middle East sent us request of high alumina balls, and advise it will be used as catalyst support media.

After checking the information, our 99% ceramic alumina balls can meet with request, even some data is much better than requests. We prepared related documents and quote to customer. Thanks for the trust from customer, we come to agreement with distributor relationship and achieved order after deep commucation and professional service.

|

|

So what is the role of high alumina balls as catalyst carriers?

1) Catalyst dispersion and activity enhancement

High alumina balls provide uniform loading sites for active components such as precious metals and transition metal oxides through their high specific surface area (150-220m ²/g) and controllable pore size (around 18 Å), reducing the amount of precious metals used while improving dispersion and stability.

2) Mechanical strength and high temperature resistance performance

The mechanical strength of high alumina balls can reach 45-65N/piece, and the compressive strength can reach 78N/mm². Usually for this application, 3mm~13mm are often used. They can adapt to high temperature and high pressure reaction environments (such as petroleum cracking and hydrogenation reactions), reducing the risk of catalyst bed wear and deactivation.

3) Optimization of pore structure

Through techniques such as multi-stage temperature gradient leaching, high alumina balls can form a dense pore structure (pore volume 0.45-0.75ml/g), suppress sintering and coke deposition, and extend the service life of the catalyst.

4) Environmental Protection and Adsorption Function

High alumina balls can adsorb pollutants such as fluoride ions (with a capacity of 6400g/m³) and sulfides, and are used for wastewater treatment and exhaust gas purification. They can also be regenerated and reused by heating (175-400 ℃).

In August, one of customer from Middle East sent us request of high alumina balls, and advise it will be used as catalyst support media.

After checking the information, our 99% ceramic alumina balls can meet with request, even some data is much better than requests. We prepared related documents and quote to customer. Thanks for the trust from customer, we come to agreement with distributor relationship and achieved order after deep commucation and professional service.

|

|

So what is the role of high alumina balls as catalyst carriers?

1) Catalyst dispersion and activity enhancement

High alumina balls provide uniform loading sites for active components such as precious metals and transition metal oxides through their high specific surface area (150-220m ²/g) and controllable pore size (around 18 Å), reducing the amount of precious metals used while improving dispersion and stability.

2) Mechanical strength and high temperature resistance performance

The mechanical strength of high alumina balls can reach 45-65N/piece, and the compressive strength can reach 78N/mm². Usually for this application, 3mm~13mm are often used. They can adapt to high temperature and high pressure reaction environments (such as petroleum cracking and hydrogenation reactions), reducing the risk of catalyst bed wear and deactivation.

3) Optimization of pore structure

Through techniques such as multi-stage temperature gradient leaching, high alumina balls can form a dense pore structure (pore volume 0.45-0.75ml/g), suppress sintering and coke deposition, and extend the service life of the catalyst.

4) Environmental Protection and Adsorption Function

High alumina balls can adsorb pollutants such as fluoride ions (with a capacity of 6400g/m³) and sulfides, and are used for wastewater treatment and exhaust gas purification. They can also be regenerated and reused by heating (175-400 ℃).